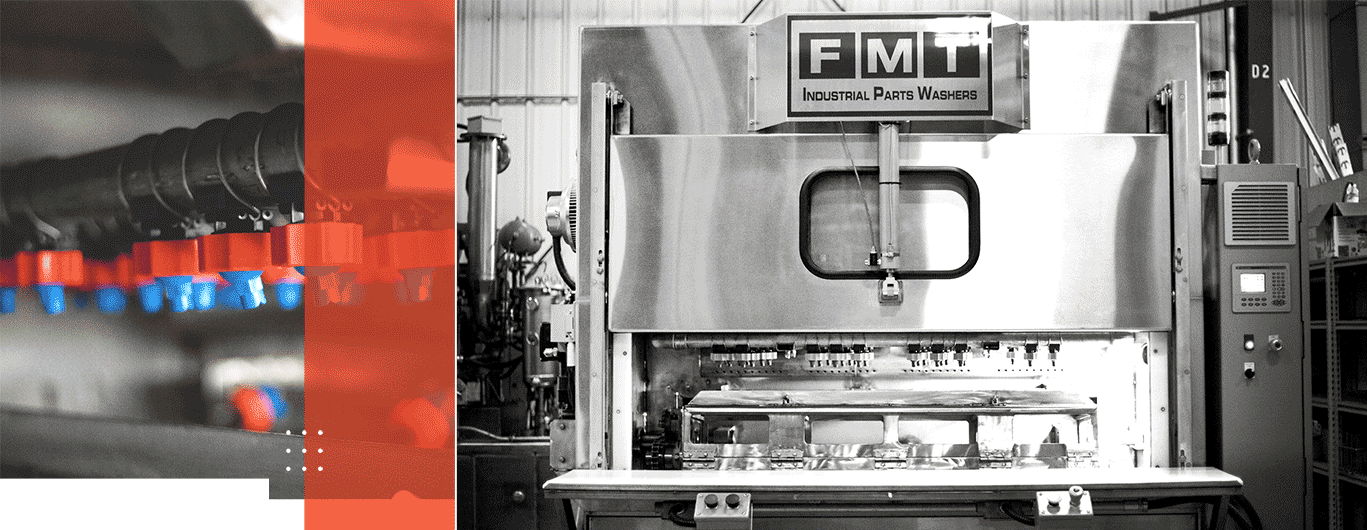

Custom Washers

Rotary Basket

Rotary basket washers are designed to accommodate a wide variety of part sizes and geometries using standard or specially designed baskets and fixtures. Best suited for batch, precision and ultrasonic cleaning, typical rotary basket washers come in 2, 4, 6 and 8 basket capacities.

Features and Options

Rotary basket machines can be configured for spray, partial immersion or full immersion; and include ultrasonics as an option. A full list of possible options are provided below. Give us a call to discuss your specific rotary basket washer requirements.

Standard Features

- Single-stage wash

- Precision spray nozzles

- 2” inch cabinet sound-proofing

- Welded pipe joints for leak-free operation

- Heavy-duty, reliable components

- Heavy gauge stainless steel construction for optimum life

- Mineral wool insulation for energy conservation

- Electric solution tank heater

- Automatic level controls w/ low level protection

- Robust drive system with variable frequency drive

- Cast iron solution pump with bag filtration system

- Allen Bradley PLC & HMI controls

- Made in the USA quality

Options

- Multi-stage (wash, rinse, blow-off)

- Additional wet stages (pre-wash, phosphate coating, rust preventative, fresh water rinse, RO or DI water rinse)

- Custom part fixtures and baskets

- Automated loading and unloading

- Stainless steel solution pump

- High-pressure and high-flow applications

- Additional filtration options (progressive, multi-bag, cartridge, magnetic, etc.)

- Filter pressure monitoring systems

- Additional heating options (gas, steam)

- Additional controls options available (relay logic, Siemens, Mitsubishi, Omron, etc.)

- Oil separation (disk skimmer, belt skimmer, coalescer)

- Sludge management (drag-out conveyor, clarifier)

- Powered exhaust (exhaust fan, mist collector)

- Noise reduction package

- Direct clean or standard

- Automated or manual rotation

- Heated rinse

- Heated dry

- PLC and HMI

- Door actuator

- Manual or automatic load/unload

- Spray/immersion wash and rinse

- Line rinse and dry

- Ultrasonic wash and rinse

No problem. We can design, engineer and manufacture a washer that meets your exact requirements.

Common Applications

- Fuel injection components

- Hydraulic valve bodies

- Engine parts

- Gear sets

- Jet engine components

- Turbo parts

- Bulk machined parts

- Commercial electronic components

Common Industries

- Automotive

- Aerospace and aviation

- Appliance

- Electronics

- Manufacturing

- Hand tools and power tools

- Military/government/defense

Talk to our commercial lenders to learn about the options available to you.

Financing >